Battery Problems in Public Transport: 7% of Fleets Affected

Battery problems in public transport are more common than most operators expect. On average, 7% of electric fleets show issues – often undetected.

Download White Paper: Why You Do Need Battery Analytics for E-Buses

TL;DR – What You Need to Know

- Around 7% of electric buses experience hidden battery faults.

- These issues are often invisible without continuous monitoring.

- Early diagnostics help prevent downtime and revenue loss.

- Support for warranty claims, resale, and daily operations.

- Field data confirms recurring patterns across fleets.

- Analytics improves fleet reliability and asset value

Operators need to prepare for battery problems in public transport by implementing fleet-wide monitoring tools.

Why Battery Problems in Public Transport Are a Matter of Scale

The electrification of public transport is accelerating. In Europe, the electric bus market grew by 22% in 2024. As fleets grow, so does operational complexity and risk. Most technical issues in e-buses are linked to the battery.

Battery Management Systems (BMS) and OEM dashboards are essential, but they lack fleet-wide, independent insight. BMS is reactive — it intervenes after a threshold is crossed. OEM dashboards often repackage the same limited data.

This leaves PTOs, insurers, and financiers with blind spots in risk and condition management.

This is why continuous battery condition monitoring is becoming essential, rather than optional, for scalable operations.

BMS + Independent Monitoring: The Full Picture

Your Battery Management System (BMS) is critical, it keeps your battery safe, balanced, and responsive.

But it’s not built to track long-term trends or compare system-wide behavior.

Adding independent monitoring allows you to:

-

-

- Detect faults before thresholds are exceeded

- Identify degradation trends that impact range and value

- Compare performance across OEMs and bus types

- Provide data for warranty negotiations and resale

- Together, BMS and analytics deliver a strategic and safety-enhancing view of battery health.

-

For a deeper look into how traditional BMS limitations are overcome with continuous battery monitoring, read our related article: From BMS to Battery Monitoring in E-Bus.

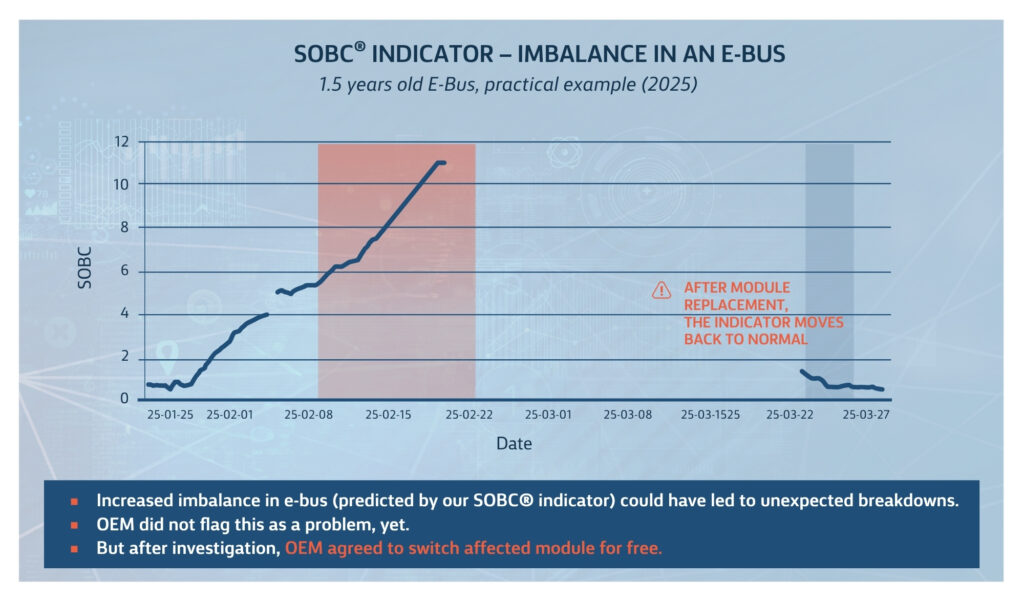

Real Example: Early Failure Detection That Standard Tools Missed

This bus was just 1.5 years old when our SOBC® indicator showed an abnormal rise in imbalance.

Although no immediate issues were reported, the data told a different story.

After we alerted the operator, the module was replaced, and the indicator returned to normal. The OEM agreed to replace the module under warranty, which prevented unplanned downtime and a financial burden for the operator ( in case it would have only caused issues after the warranty period).

“I was skeptical why we need battery analytics for a new fleet, but let me be honest:

Already in month 1, the tool detected multiple critical batteries, which the OEM replaced at their cost.”

Director of Technology, Large Public Transport Operator

This is not an isolated case. In another fleet, battery capacity inhomogeneity appeared across several vehicles within the first 18 months. Analytics made these trends visible early.

We detail the key findings in the white paper.

What’s Actually Happening Inside the Battery?

Although batteries are safer than ever, statistics don’t lie. In large fleets, 7% of buses experience issues, such as safety concerns, reduced range, and unexpected downtime. Below are a few battery issues that we often see during our daily continuous battery monitoring of electric buses:

Voltage Drift:

Gradual imbalance in cells leading to reduced usable capacity.

Disconnected Modules:

Temporary loss of modules, lowering available energy and range.

Overheating:

Localised temperature rises with long-term degradation or safety risks.

Premature Degradation:

Capacity fade well ahead of expectations.

These are not one-off anomalies; they are recurring patterns observed across fleets. This leads to limited range, stressed adjacent cells, and lower residual value — all while remaining undetected without analytics.

The UITP reports that many e-bus battery contracts last 8–10 years, but the real-life battery lifespan is often 6–8 years.

The difference between the two is where the surprises — and costs — hit hardest.

Checklist: Preparing for Battery Problems in Public Transport

Download the Battery Planning Checklist for PTOs.

For PTOs, proactive planning is essential:

- Expect it: Assume 7% of your fleet will show issues at any time

- Monitor beyond the standard tools: Use independent analytics platforms like volytica’s vdx sentry.

- Plan for mid-life replacements: Contracts should reflect real battery behavior

- Create alert thresholds: Use trend-based triggers or contract-based thresholds, not just system alarms.

- Benchmark performance: Integrate analytics into your fleet management system to compare across buses and fleets, not just within a single OEM.

By reframing the problem from “avoidance” to “management,” PTO’s can stay in control.

Download the Full White Paper

“Why You Do Need Battery Analytics for E-Buses” (available in English and Spanish)

Full insights, case studies, and operator experiences from volytica.

📚 Reading Tip: The “Battery Cycle” Returns

State of Charge – More Than Just a Number.

The latest release from The Battery Cycle explores battery chemistry and real-world challenges like SOC estimation — a critical topic for fleet operators working with electric mobility or BESS.

This marks the 2025 relaunch of Sustainable Bus’s long-running knowledge series, now featuring insights from Volytica CEO Claudius Jehle. Three new articles are already live, with more on the way.