What Batteries and Yogurt Have in Common: Understanding Stress, Aging, and Risk in eBus Fleets

*Original in Spanish, published 2025-04-25 in the magazine Carril Bus by Mayte

At first glance, batteries and yogurt might not seem to have much in common. But both have a shelf life, both respond poorly to stress, and both can behave unpredictably as they age, especially when stored or used under the wrong conditions. For public transport operators managing electric buses, understanding battery aging is becoming just as important as knowing how to keep vehicles on the road.

During the recent panel discussion at Motortec’s Espacio Digital Motor, several Spanish public transport operators – including TUSSAM, TMB, EMT Madrid and Guaguas Canarias – highlighted a pressing need: better access to vehicle data and deeper technical insight for their electric bus fleets.

One critical area is often underestimated: the battery. Although they account for up to 60% of a vehicle’s cost, they remain largely opaque in day-to-day operations. Fleet managers and technicians are increasingly reporting challenges: unexpected failures, diminishing range and, in rare cases, battery-related safety incidents.

The issue is not only technical, but structural. Built-in Battery Management Systems (BMS) play an important role in system safety, but they are not designed to provide long-term analytics or predict faults in advance. This makes it difficult for operators to differentiate between normal wear and actual risk or to plan replacements and interventions efficiently.

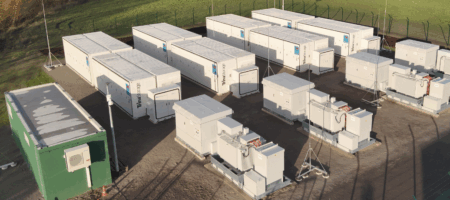

Across Europe, some operators have begun using dedicated diagnostics platforms to monitor battery health in real time. These tools analyze large amounts of data from the vehicle’s systems to detect anomalies early, provide clear alerts, and offer insights that support better decision-making across operations, maintenance, and asset management.

“Many fleet operators face battery related uncertainties, especially as their vehicles age,” explains Florian Stern, Head of Business Development at volytica. “With the right monitoring in place, we can reduce avoidable downtime and give technical teams clarity where traditional systems leave gaps.”

At Motortec, a joint approach by volytica and ZF Aftermarket was presented. It allows operators to integrate battery diagnostics into the existing ZF Bus Connect environment – providing insight without the need to install additional hardware. Similar integration is possible with other established fleet service platforms, including those from Stratio, Cojali and Bled, which are widely used by Spanish operators.

Gerrie Geeraerts, Global Sales & Operations Leader Digital Solutions at ZF Aftermarket, added: “ZF Bus Connect has always focused on improving cost efficiency and operational effectiveness for bus operators. By integrating battery diagnostics into our system, we help our customers make more informed decisions about vehicle health – without adding complexity to their operations.”

With over 1,500 electric buses in operation across Spain, the importance of battery monitoring is likely to grow further. As more data becomes available, the ability to detect issues early, extend battery life, and support resale or second-life planning could become a standard part of fleet management, especially for operators aiming to ensure reliability while managing cost.

Head of Business Development

Our Head of Business Development, Florian Stern, can provide deeper insights.

Please contact him directly: florian.stern@volytica.com.