From BMS to Monitoring: Dual Battery Safety Approach

*Original in German, published 2025-06-10 in the magazine NahverkehrsPraxis, edition 05-06

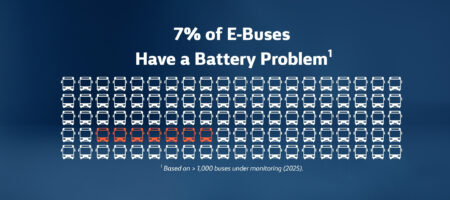

The electrification of bus fleets is progressing rapidly worldwide. More and more cities and municipalities are relying on locally emission-free, battery-powered electric buses to reduce air pollution and noise in urban areas. However, as this technology becomes more widespread, the demands on fleet management and vehicle safety increase. At the center of this challenge is the battery — the most expensive and critical component of an electric bus. Monitoring the battery’s condition and detecting anomalies early on are essential to avoiding costly failures and safety risks. This highlights the growing importance of battery monitoring in E-Buses as a strategic measure in fleet safety and reliability.

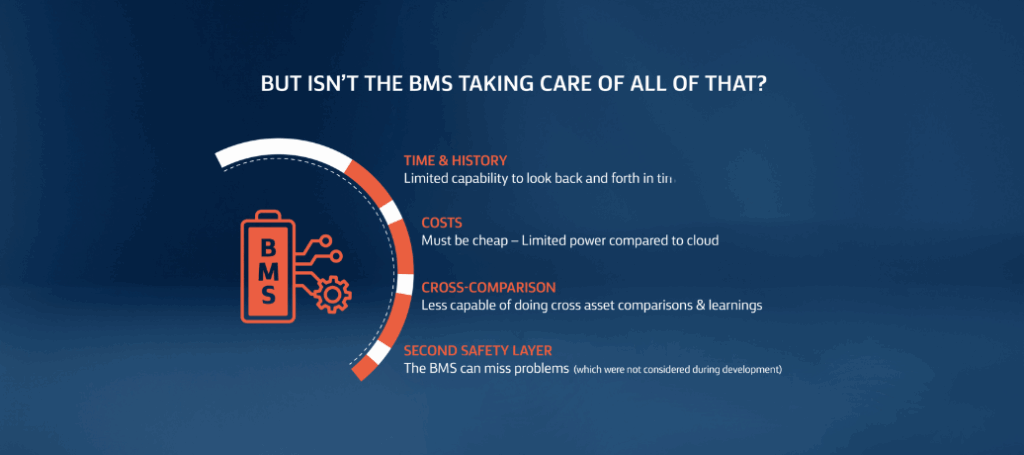

Limits of Classical BMS (Battery Management Systems)

Traditional Battery Management Systems (BMS) are responsible for the basic monitoring of battery cells in vehicles. They measure parameters such as voltage, current, and temperature, and calculate indicators like the State of Charge (SOC). However, these systems often reach their limits when it comes to detecting gradual or microscopic defects.

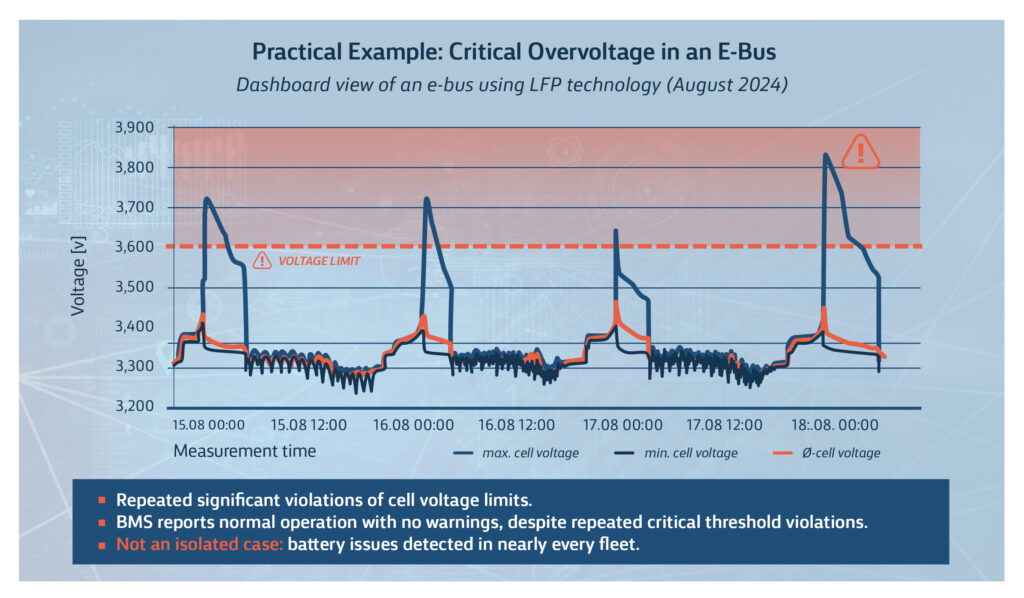

Anomalies, for example imbalanced¹ cells, often develop over long periods and remain undetected because BMS typically only react to acute threshold violations. Even these threshold monitoring functions have limitations, as shown by the example of a 10 month old bus. At least one cell of the battery system repeatedly experienced significant overcharging. Without the additional online monitoring by volytica diagnostics, this issue would have gone unnoticed and could have led to a safety risk – or at the very least, a premature loss in battery performance.

Why SOH Doesn’t Equal Safety

Another challenge in fleet electrification is the significant emphasis placed on the State of Health (SOH) of the battery. This metric provides information about the remaining capacity compared to the new condition, but offers limited insight into actual safety. Batteries with an SOH above 90% may exhibit severe internal damage, including lithium plating², without the BMS issuing any warnings. A realistic assessment of battery safety requires additional indicators and continuous data analysis.

Typical Anomalies – Insights from Practice

Continuous battery monitoring in E-Bus fleets has shown that certain anomalies occur repeatedly. One common issue is the previously mentioned imbalances. These are found in nearly all monitored fleets and across various OEMs, meaning they are not necessarily due to poor product quality.

Another phenomenon is threshold violations. Besides potentially breaching warranty conditions, these also accelerate battery aging and generally pose safety risks.

Cell quality issues are also a concern. Manufacturing-related weaknesses or overly generous tolerances can lead to individual cells aging faster or failing. The larger the fleet, the more likely isolated defective cells will appear. This is a major safety risk for fleet operators if these anomalies remain undetected.

Additional Indicators and Continuous Cloud-Based Battery Analytics

volytica diagnostics’ cloud-based analysis requires only the minimal dataset specified by VDV238³ for continuous evaluation. No additional sensors are necessary. Integrating the data into a centralized cloud allows for the calculation and monitoring of additional indicators. While traditional BMS systems are designed to monitor and record current states, cloud-based systems have the capacity to incorporate historical data, providing a more comprehensive view of system performance. This allows for the identification of acute issues as well as the tracking of long-term developments, which provide insights into battery aging and safety. A key benefit of battery monitoring in E-Buses is the early detection of deviations in operating behavior. Real-time analysis of temperature, voltage, and charge cycle trends enables proactive response to wear and defects by operators. This approach reduces the likelihood of failures and extends the lifespan of batteries. Continuous monitoring provides an additional layer of safety, enhancing the capabilities of traditional BMS. This approach ensures the safe and efficient operation of electric bus fleets.

Relevance for Operators, Workshops, and OEMs

Proactive battery data monitoring provides decisive advantages for various stakeholders in public transport:

- Operators: Reduced unplanned downtimes and minimized safety risks.

- Workshops: Accurate diagnostics for targeted repairs.

- OEMs: Long-term performance data for optimized product development.

Introducing continuous monitoring ensures transparency regarding battery condition and enables early detection of potential failures for targeted intervention.

Conclusion: Monitoring as a Second Layer of Safety Alongside the BMS

Traditional BMS fulfill important basic functions but are not sufficient for comprehensive battery monitoring in electric buses. Only through additional, continuous, cloud-based battery data analysis can gradual defects and safety-critical anomalies become visible. This creates a second layer of safety that not only extends the lifespan of batteries but also significantly increases safety in public transport.

Author: Lutz Morawietz

Lutz Morawietz, Head of Algorithm Development at volytica diagnostics, has spent years developing algorithms and conducting experiments following his degree in electrical engineering.

His goal has been to explore the complexity of battery data. With over two decades of experience in battery testing, algorithm development, and research, he has dedicated his career to understanding the most expensive and critical component of the energy transition: the battery.

For the past five years, he has spearheaded the development of algorithms at volytica diagnostics. In this role, he is responsible for analyzing battery data to identify areas for improvement and implementing these insights to enhance performance and efficiency. Driven by his passion for the energy transition, he is committed to ensuring that every battery reaches its full potential and contributes to a more sustainable and efficient energy landscape.

Please get in touch for further information.

Battery Glossary:

¹Imbalanced refers to an uneven distribution of charge among the hundreds of cells within a battery system. Ideally, all of these cells would behave identically at all times. This is because the overall performance capability is determined by the weakest link! Imbalances are only partially detectable by the BMS. Trend analyses and identifying the underlying causes are practically impossible without contextual information. One example of a measurement unit is the state of balance charge (SOBC), which has a counterpart in the state of balance thermal (SOBT). The latter reflects thermal balance and highlights irregularities in the battery’s thermal management system. Other measurement units are also commonly used.

²Lithium plating refers to the gradual deposition of metallic lithium, which is primarily caused by unfavorable charging processes. It leads to reduced battery performance and an increased safety risk.

³VDV-Schrift 238: Fahrzeugdaten in Bussen des ÖPNV / vehicle data in buses in PT: https://knowhow.vdv.de/documents/238/